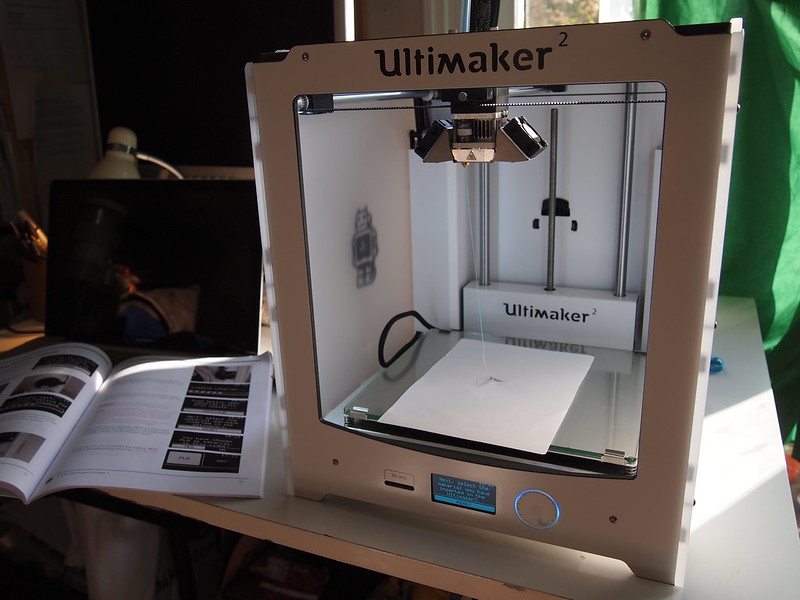

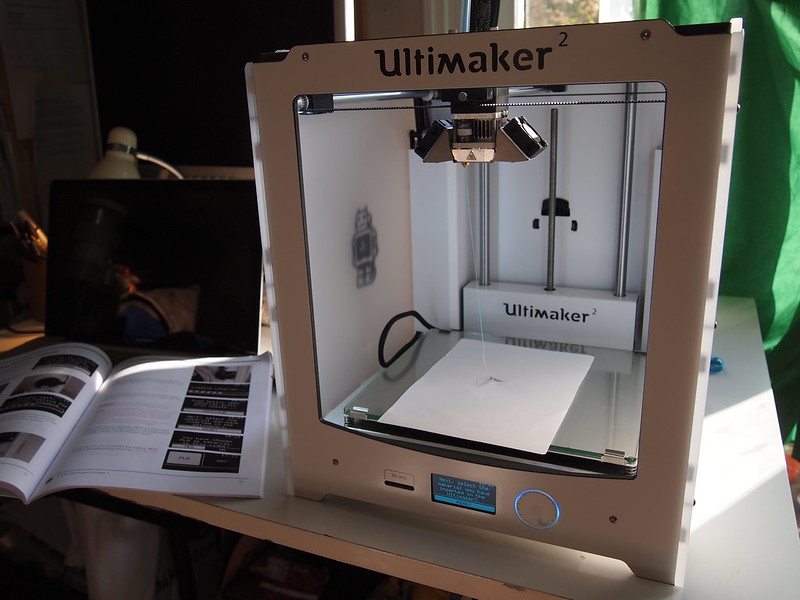

This week I bought an Ultimaker 2 so I could start work on a new project in which I intend to do a fair bit of prototyping and printing with different materials. I want to understand how a 3D printer works instead of handing my file over to someone to make the print for me - the same way a printmaker learns the intricacies of the printmaking process. In my mind, I thought it would be like just having a printer which poops out 3D models. But that was wrong. This is more like having a baby which is lovely when the baby is being lovely, but then you find that it does not have the ability to tell you what is wrong with it, and all you can see is that sometimes stuff might be coming out of it in rather unexpected ways. Horrifying ways. Oh and the sounds! The sounds which might be delightfully high-tech if you're in a good mood, or monstrous if you're in an irritable mood.

Now, if someone were to ask me, "Should I get a 3D printer?", my answer would be "Do you like fixing 3D printers? DO YOU??? DO YOU LIKE STRUGGLING WITH ALLEN KEYS AND PILERS FOR HOURS?" Let's just face it - it appears that maintenance and fixing is going to be a big part of having a 3D printer. I feel like a person who has stupidly moved into the top floor of an apartment block without a lift. "Why yes, I don't mind living on the top floor penthouse with no lift access, I don't mind getting a little more exercise every day or having to hauling up my boxes up and down all these painfully endless flights of stairs!"

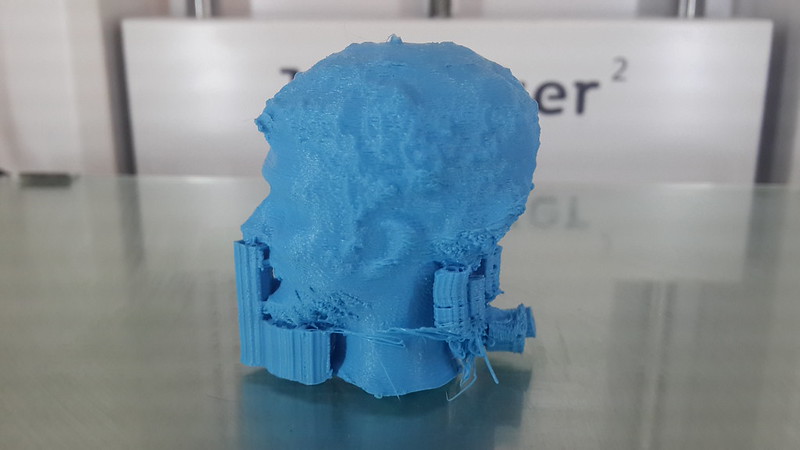

The first prints were all fine. I thought it was quite noisy though but we took it back to the iMakr engineers to check and they said it was normal. Perhaps this is down to my furniture all being quite hollow. I think we can live with the noise, which is like a whirring melon of sorts. When it returned from the engineers, the first print I did after that had some underextrusion, causing one of my prints to snap into half when I was removing it from the build plate.

Again, I'm no engineer, so it has been taking considerable time for me to really understand each part of the printer and fix what seem like minor issues... which then turn into many frustrated hours poking and tinkering with the machine. For example, I thought I had a nozzle problem but found out it was the filament feeder that was the issue and grinding the filament too tightly at the feeder.

Knurled wheel had begun to grind the filament...

After some confusion of whether I should try to adjust the tension or to change the temperature or speed, I determined that it might just be a physical blockage and that I had to remove the bowden tube to manually pull out the jammed filament with pliers. The logic behind not upping the speed is that if you have an existing blockage, sending more material down the pipe at a faster rate doesn't necessarily help the jam. I ended up having to go through the assembly manual and trawling the forums, wishing I had some calipers now to measure if my filament was INDEED 2.85mm as claimed or thicker in some parts and causing the jam, and falling into depression and demoralisation when I couldn't exert enough strength to pull the jammed filament out of the Bowden tube (George had to help me with this).

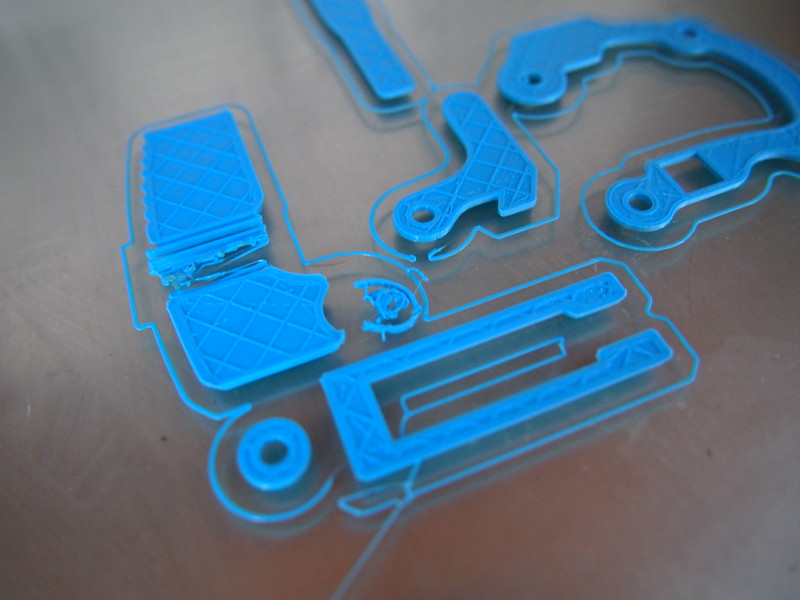

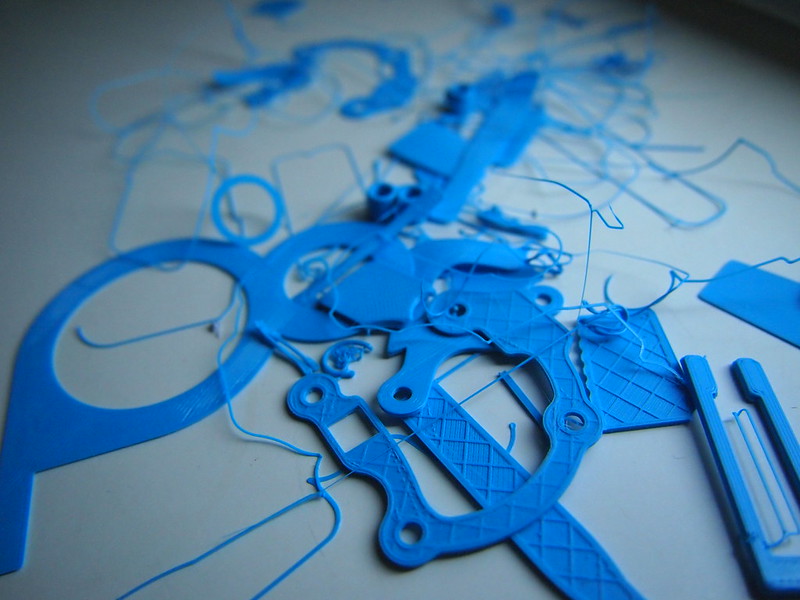

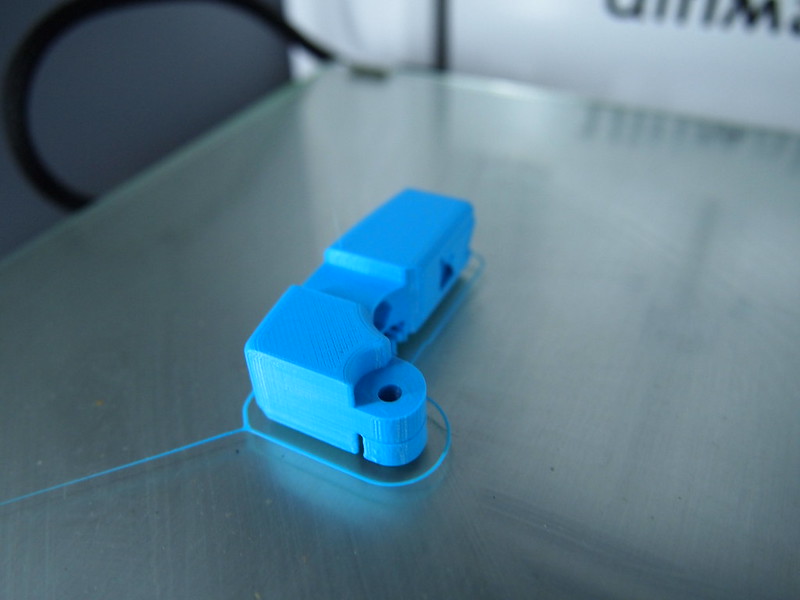

From left to right: “Yet Another Ultimaker 2 Feeder” by sfriedri on YouImagine (combination of |Robert| and Geeks’s Design), Ian Spring's Ultimaker 2 Feeder, |Robert|'s Ultimaker 2 Feeder with filament guide.

From looking around at different people's modified feeder systems and from playing with the Bowden tube, I've determined that the issue is that the filament could benefit from some straightening before entering the bowden tube. Furthermore, if the spring tension was easier to change without the tiny finicky allen key, this would be an improvement.

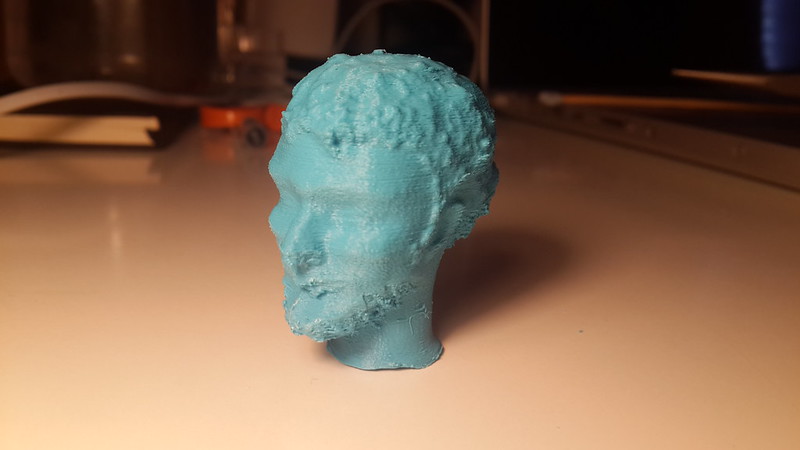

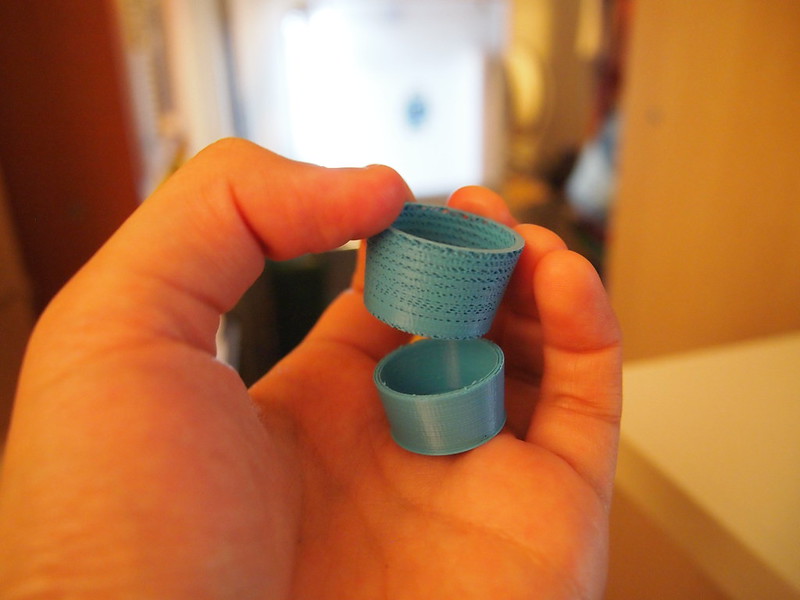

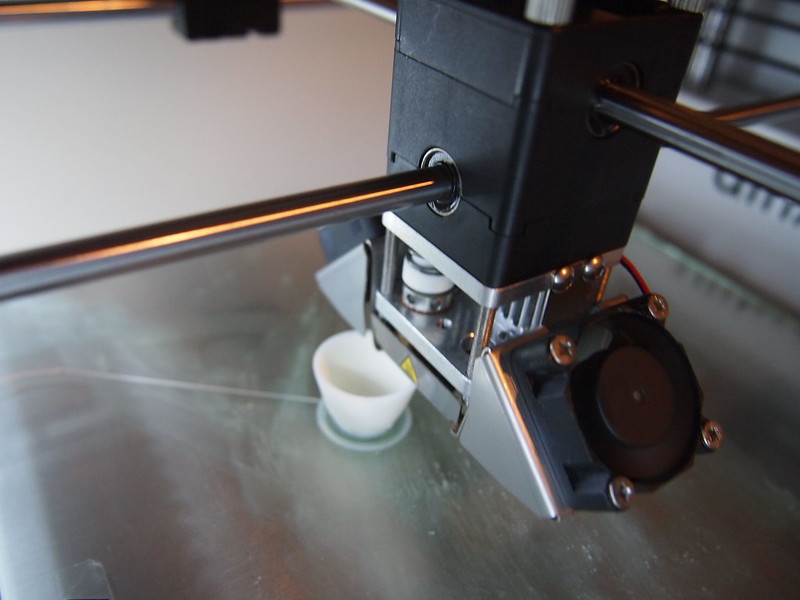

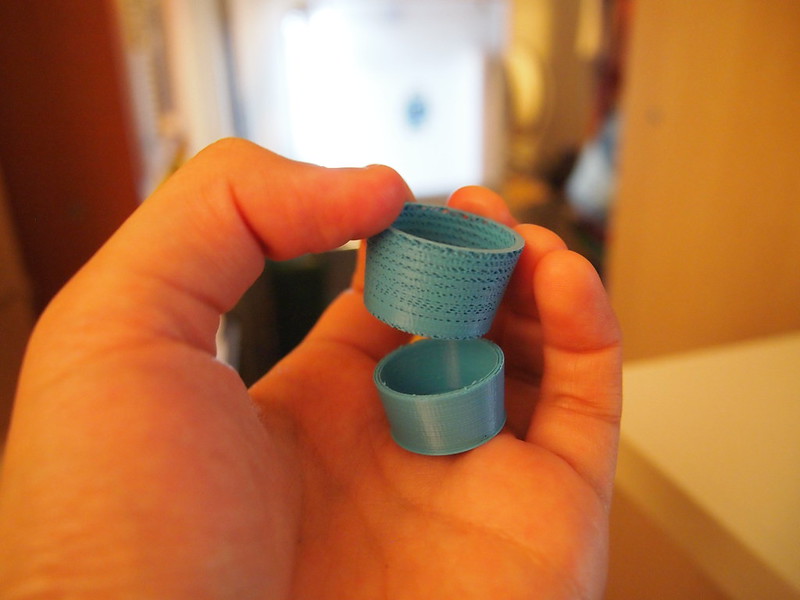

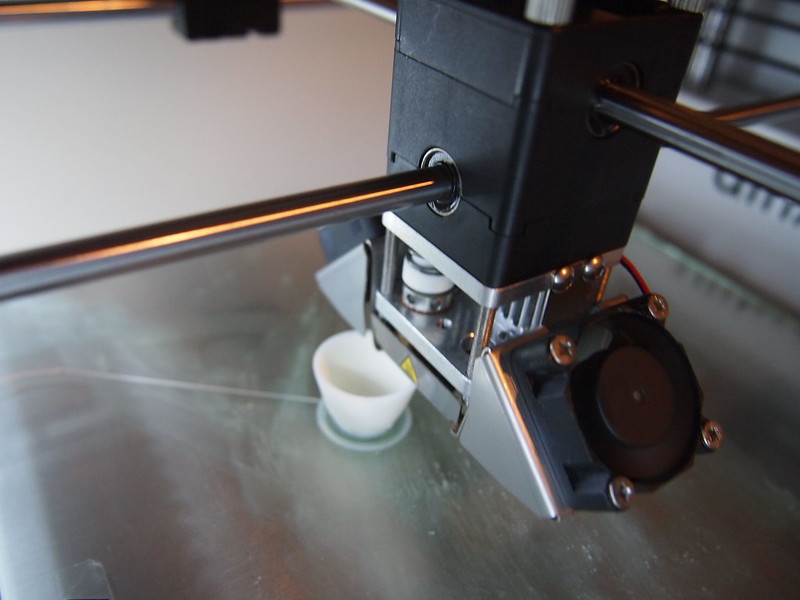

After fixing the jam I switched to white PLA and printing has resumed just fine and I made lots of tiny dollhouse cups as a quick test.

One might say that with a 3D printer you would never have to buy as many things again since you could print it in the convenience of your own home. But convenience? Oh yes, just give me a few hours while I print this spoon instead of going outside to a shop to buy one in a heartbeat. It is a slow and hard process of getting to know the machine bit by bit along the way. Well this week I became acquainted with the filament feeder. All I can say is that I was amazed that I managed to fix it all at the end without making anything explode.

LESSONS LEARNT THIS WEEK WITH THE UM2

UNDEREXTRUSION TROUBLESHOOTING:

- Underextrusion - could be either a nozzle jam or filament jam. To confirm if it is a filament jam, check whether the filament can be removed or reversed. If the filament cannot be removed then its a filament jam

- If its a

nozzle jam, which might happen if switching between PLA and ABS (which melt at different temperatures), you can clear it using

the Atomic method.

- If its a

filament jam, remove the jammed filament from the feeder and Bowden tube. Remove Bowden tube by first removing tiny blue horseshoes and pressing down on the white tighteners while pulling bowden tubes out. Do this for both ends. Then remove the misbehaving filament from the tube with a pair of pliers and replace them all back. If warping or deformation of the Bowden tube has occurred (which seems likelier to happen on the feeder end), trim a bit off but with a very flat and straight razor cut across.